In a bid to answer accelerating sewage waste issues and provide support to local agriculture, Nexus W2V, LLC (Nexus W2V), a developer of waste-to-value infrastructure assets, plans to make Allegany County the site of a plant for nutrient- and carbon-rich biochar. The company joins a growing community of circular economy-focused businesses (enterprises dedicated to reusing and recycling materials to reduce waste and conserve resources) in the Cumberland North Branch Industrial Park.

Formed two years ago by Nexus Program Management Group, LLC (an investment and consulting company for sustainable infrastructure, renewable energy, and waste-to-value), Nexus W2V expands the company beyond the boardroom and into a larger, actionable role in sustainability initiatives. Nexus W2V’s Allegany project is a solution to Maryland’s rising sewer sludge waste issue and plans to transform waste into biochar. When applied to farmland, biochar encourages fertile crops, promotes water retention, and improves agricultural sustainability.

Until recently, sewer sludge products required little treatment before being processed for farmland soil. The growing presence of contaminants such as pharmaceutical residue, microplastics, per- and polyfluorinated substances (PFAS), and other impurities has forced more stringent “cleaning” procedures to make the material safe for application on farm fields.

Brecc Avellar, Nexus W2V’s Senior Project Developer, emphasizes, “These contaminants have raised the disposal costs for sewage sludge, and many landfills are turning away the materials. Contaminants are an especially big problem for coastal states, including Maryland.”

Densely populated areas currently must transport sewer waste from major wastewater treatment centers to distant disposal areas. “Baltimore City, for example, needs to transport waste to Ohio using railroad carts for proper disposal,” notes Avellar.

Knowing that a disposal solution was needed in the area, Nexus W2V contacted state and local entities to determine the best location for a processing facility. Nexus W2V was encouraged to consider Allegany County for its new plant.

Allegany uniquely met Nexus W2V’s project needs: access to natural resources, such as green wood waste; history in heavy industry; knowledgeable workforce; and streamlined permitting process. The county’s burgeoning reputation for, and positioning near, other sustainability-focused businesses sealed Nexus W2V’s decision.

“Part of what drew us to Allegany County was their desire to have this cluster of circular economy businesses." - Brecc Avellar, Senior Project Developer, Nexus W2V.

Economic Development Specialist for Allegany County Economic and Community Development, Adam Strott, notes, "Allegany County is uniquely positioned to capitalize on new technological trends in the circular economy. Given our proximity to multiple major markets and existing infrastructure, these future-proof industries will help to make Allegany County competitive in the 21st century, providing ample opportunities for long-term career growth. Nexus W2V's project at the North Branch Industrial Park has the potential to not only create opportunities in this emerging industry but is also the first piece to further developing our innovative wood products industry."

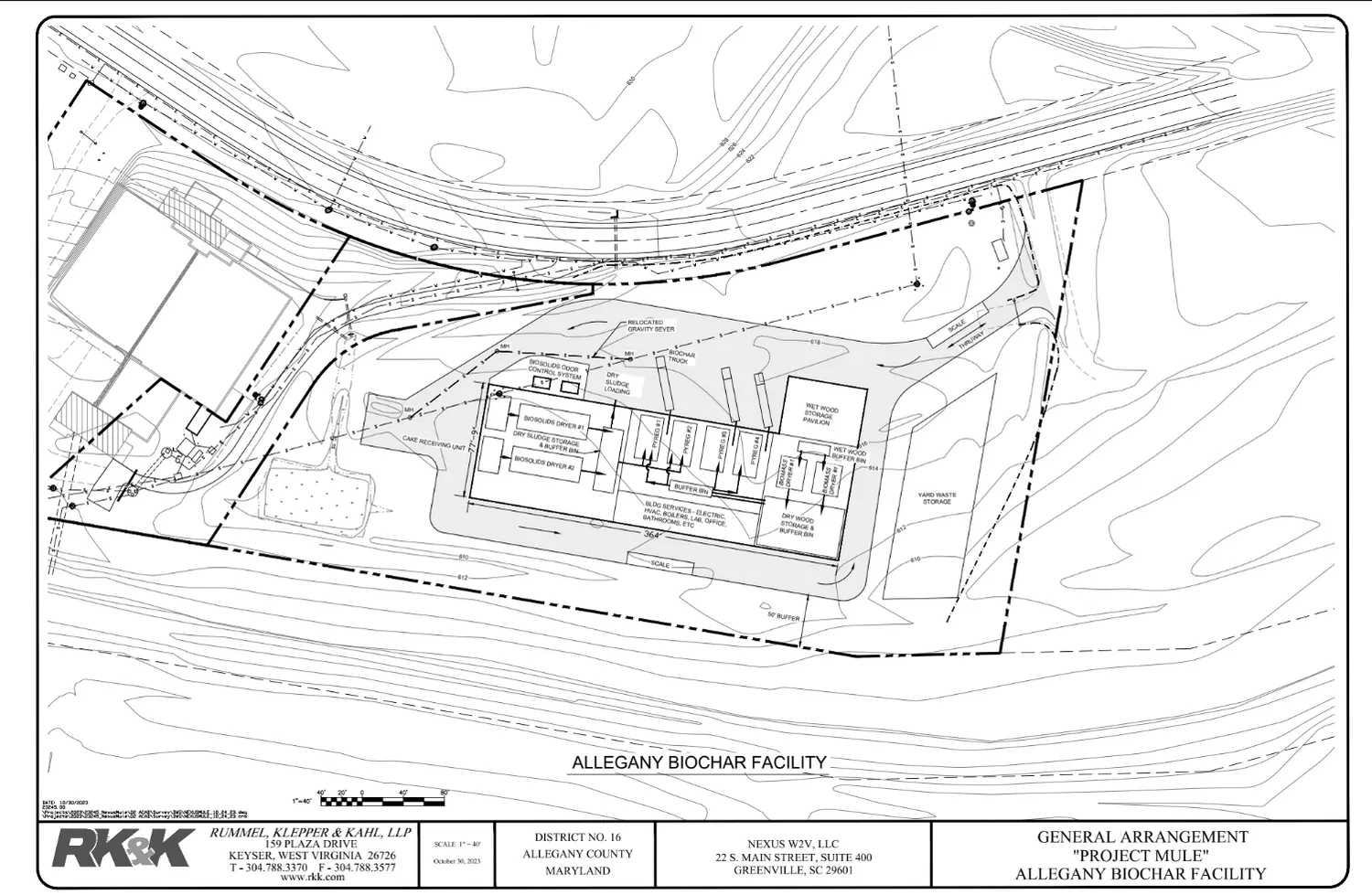

Bolstered by the support of Allegany County Economic and Community Development, Nexus W2V began to plan a facility in Cumberland that will employ eight to ten workers.

The Nexus W2V’s Allegany plant will be a pilot project to prove the process is viable for other counties. “The process we are using has been used for 20 years in Europe. Nexus W2V will demonstrate that this can all be done safely and economically and that we can get the process permitted in a streamlined manner.”

Presently, the facility site is a drop-off location for wood waste used by local landscaping companies, and local residents. The site’s access to wood waste is a natural advantage for Nexus W2V, as wood waste needs to be incorporated into the dried sewer solids to create the final biochar product.

Andrew Cowan, Recycling Coordinator for Allegany County Department of Public Works remarks, “We are excited about the proposed biochar facility. While the site will be privately owned, [Nexus W2V] will still allow free drop-off of yard waste for residents. This means we are still able to offer the same recycling opportunities without the need for tax dollars to subsidize the program."

“Many parts of the U.S. don’t have the knowledge base we’re looking for. A lot of the local workforce already have the skill sets that we need for these types of industrial processes.” - Brecc Avellar, Senior Project Developer, Nexus W2V.

Trucks hauling the sewer sludge, sourced from state and local waste centers, will deliver materials inside the plant to limit odors and other contaminants. The sludge will undergo a three-step process to dry, render harmful chemicals inert, and prepare the sewage.

- Drying: Made up of 75% water, the sludge will be added to a ‘gigantic clothes dryer’ and dried until it is 10% water.

- Pyrolysis: The material is then subjected to “pyrolysis,” where it is further dried using indirect heat. This process occurs in an air-free environment to prevent flame development in the system where the solids are processed.

- Heating: Finally, the off-gas vapors are heated in a controlled furnace at temperatures exceeding 1000 degrees Fahrenheit. During this phase, the vapor released in the drying and pyrolysis stages is oxidized into carbon dioxide (CO2) and water. Additionally, PFAS chemicals are broken down into mineral salts and CO2.

“The pyrolysis and controlled vapor furnace renders the biosolids into an inert organic material, high in minerals such as potassium and phosphorus. These solids will be mixed with traditional compost and wood biochar (separate process) to make a safe final product for agricultural use.”

On the other side of the building, the wood waste is transported by conveyor systems and mixed with the dried sludge, or solids, using a tumbler. According to Avellar, the final product resembles the carbon that typically goes in fish filters. Annually, Nexus W2V estimates they will be processing 20,000 to 25,000 tons of sewage solids and up to 10,000 tons of wood chips. Nexus W2V expects to produce 6,000 to 10,000 tons of final biochar product annually.

Due to state regulations, the material cannot be kept onsite overnight, so materials are dried, mixed, and sent out all on the same day. The biochar will be blended with compost and mulch off-site. Nexus W2V will partner with an organic fertilizer application company based in Western Pennsylvania to distribute the final mix onto local farmlands.

The U.S. Department of Agriculture (USDA) offers reimbursement programs to farms that increase the carbon content in their soil. Working with this program, Nexus W2V will find homes for the final product. At an application rate of one to two tons per acre, Nexus will need to find six to ten thousand acres of farmland to utilize the nutrient-dense product.

A public meeting is set for 5 p.m. on Tuesday, January 30th, at the Allegany County Economic Development Office to answer questions on the upcoming project. Pending permit approval, the site is set to open in late 2024 for operations in early 2025.

“We want to be a really good corporate neighbor, so we’re very excited to be in Allegany County and around Cumberland,” Avellar concludes.

Read other business stories from Allegany County, here.