Western Maryland Works (WMW) at Allegany College of Maryland is helping local residents build in-demand skills, prototype products, and pursue new career pathways through a facility designed to strengthen the region’s workforce and entrepreneurial ecosystem. This kind of on-the-ground work is an economic development asset for the region. It expands access to training and tools that help Allegany County residents build skills and help small businesses grow.

Operating through Allegany College of Maryland, WMW brings together training, equipment access, and technical support. This resource was created to address regional workforce needs (particularly in the trades), while also supporting residents who want to prototype products and grow a local business.

Shawn O’Rourke, Director of Western Maryland Works, describes WMW as a single operation with three complementary “legs,” or functions. Those legs include advanced manufacturing Training, a makerspace, and Engineering Technology programs they also offer safety certifications, hands-on technical training, and more. As a whole, these legs create multiple entry points for people at different stages: students exploring their options, adults shifting careers, entrepreneurs prototyping a product, and employers searching for skilled talent.

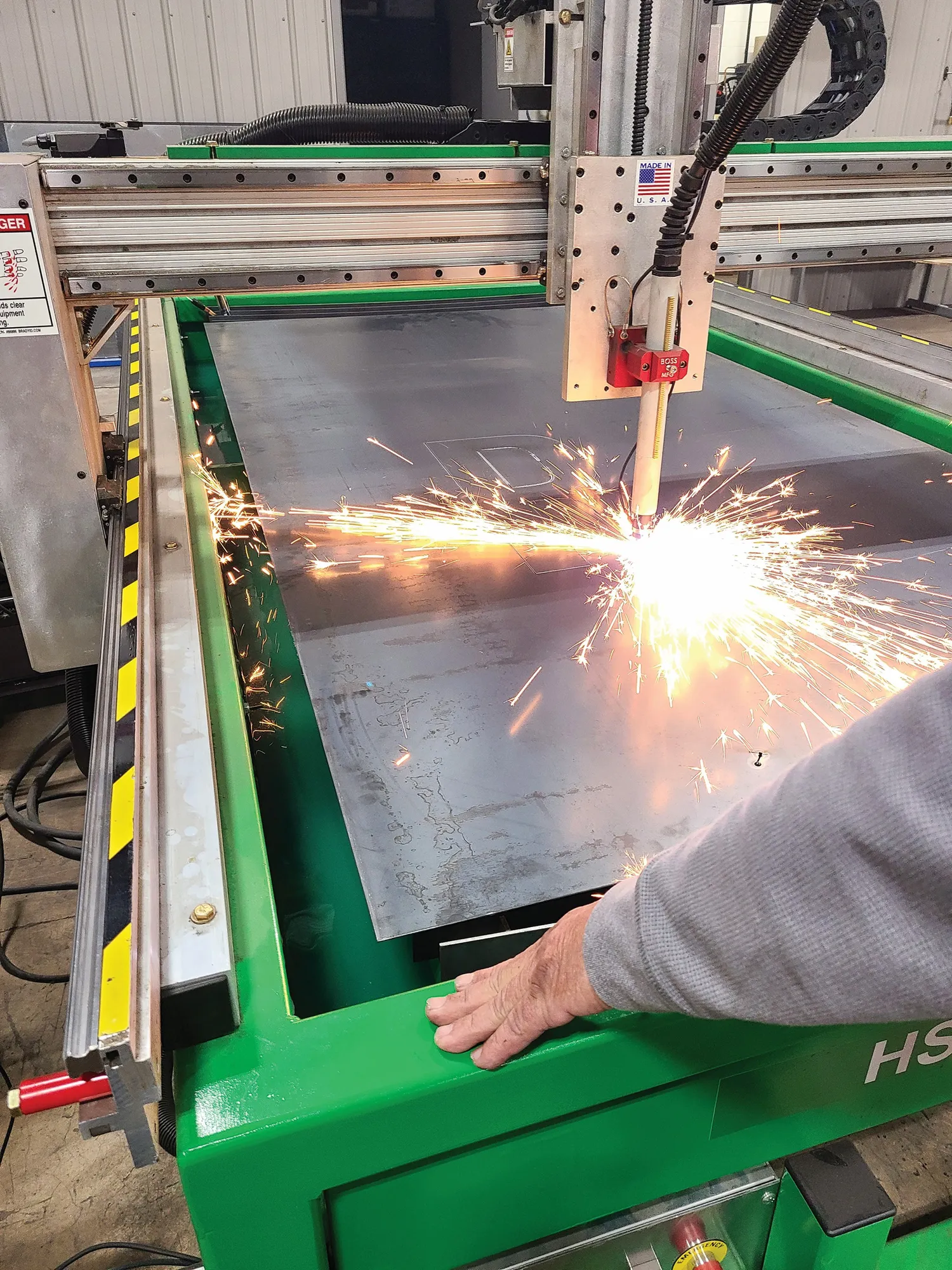

The makerspace model is a core part of that access. “It’s membership-based,” O’Rourke explained, which helps reduce cost barriers to equipment that individuals and small businesses typically cannot justify on their own. Instead of requiring a major capital investment before someone can even begin, the makerspace creates an environment where people can learn, experiment, and produce with guidance from staff who know the tools and processes. It helps residents move from training to production and, in some cases, to new income streams.

A key point, O’Rourke said, is that Western Maryland Works is not a production shop. “There’s a misconception sometimes that we make things here,” he said. “We don’t; we enable you to make them. We give you the skills and the coaching to do it yourself.” Participants walk away with transferable skills they can refine over time and use in a job setting, a small business, or a new venture.

O’Rourke often sees that transformation begin with something informal: an idea sketched out on paper, or a concept someone has been sitting on for years. “If they have an idea, they can come here and work with the people and the equipment and take that idea from concept to reality,” he states. For many people, that first completed project changes what they think is possible. That is the kind of progress and confidence-building that WMW strives to support.

William Baxter, Lead Technician for the WMW makerspace, sees the growth curve in real time. He recounts what happens when people return consistently and learn to run their own projects from start to finish, through trial and error: “Over time, they start becoming fully self-sufficient.” That progression is visible in the range of work produced in the makerspace.

Baxter shared the example of Dimitri, a maker who works for a medical company and uses the makerspace to produce items such as sample trays. Dimitri’s progress came through testing materials, adjusting designs, and refining process details until the outcome met the needed standard. Along the way, Baxter said, Dimitri developed stronger design capabilities and became more efficient with production planning, especially when producing higher volumes.

He also pointed to Emily, a local mom and event organizer who comes to the makerspace to complete client orders, including customized water bottles tied to community events. For makers like Emily, the value of the space is practical and cost-efficient; it allows her to deliver consistent results, offers troubleshooting support from experienced staff, and helps her scale projects without taking on the full cost of specialized equipment.

The makerspace’s impact is not limited to commercial work. Baxter described participants in the makerspace’s wood shop who began with little or no experience and now produce a range of handmade products. Mosen, another maker Baxter mentioned, started out “with no woodworking experience at all, and now he’s making all sorts of cheese trays and cutting boards for his family, as well as personal art projects.”

Another maker, Ben, spent months refining a product concept before bringing it to the community, “making different iterations of his lamp,” as Baxter put it, then exhibited the finished piece during a local artist tour and began selling it.

WMW’s adult education and workforce training programs extend that impact directly into talent development, and those programs are intentionally shaped by employer demand. “We’re going out in the community with our industry partners trying to find out what their future demand is,” O’Rourke said. “What are they looking for in three, four, five years? What’s the skill set they’re going to need?” The goal is to train residents in skills that translate into real opportunities across multiple employers and sectors, helping ensure that when jobs open, qualified candidates are already here.

Partnership makes that system stronger. WMW collaborates with schools, employers, and local support organizations, and Allegany County Economic and Community Development (ACECD) helps connect training resources to regional workforce and business needs. O’Rourke emphasizes this, saying, “It takes a village. There’s always room at the table.” That ecosystem approach matters in a rural region where every retained graduate, every new credential, and every growing small business strengthens the wider community.

Even with those assets in place, O’Rourke is candid about the primary challenge: participation. “This is an incredibly unique place in our area,” he explains. “We can’t figure out why there’s not a line out the door, and we need skilled labor.” Bridging the gap requires increased awareness and shifted mindsets, specifically in how younger people view hands-on careers, as well as clearer on-ramps for adults who are ready for a change.

O’Rourke invites Allegany County residents to visit WMW firsthand. “Our doors are open for tours. If you’ve got someone who you think would benefit from this place, bring them,” O’Rourke said. Whether individuals are exploring new careers, building side businesses, or looking for resources that support next steps, WMW is designed to help residents move from interest to action.

To learn more about Western Maryland Works and how it supports workforce development, entrepreneurship, and economic growth in Allegany County, visit our blog for additional stories and local resources.